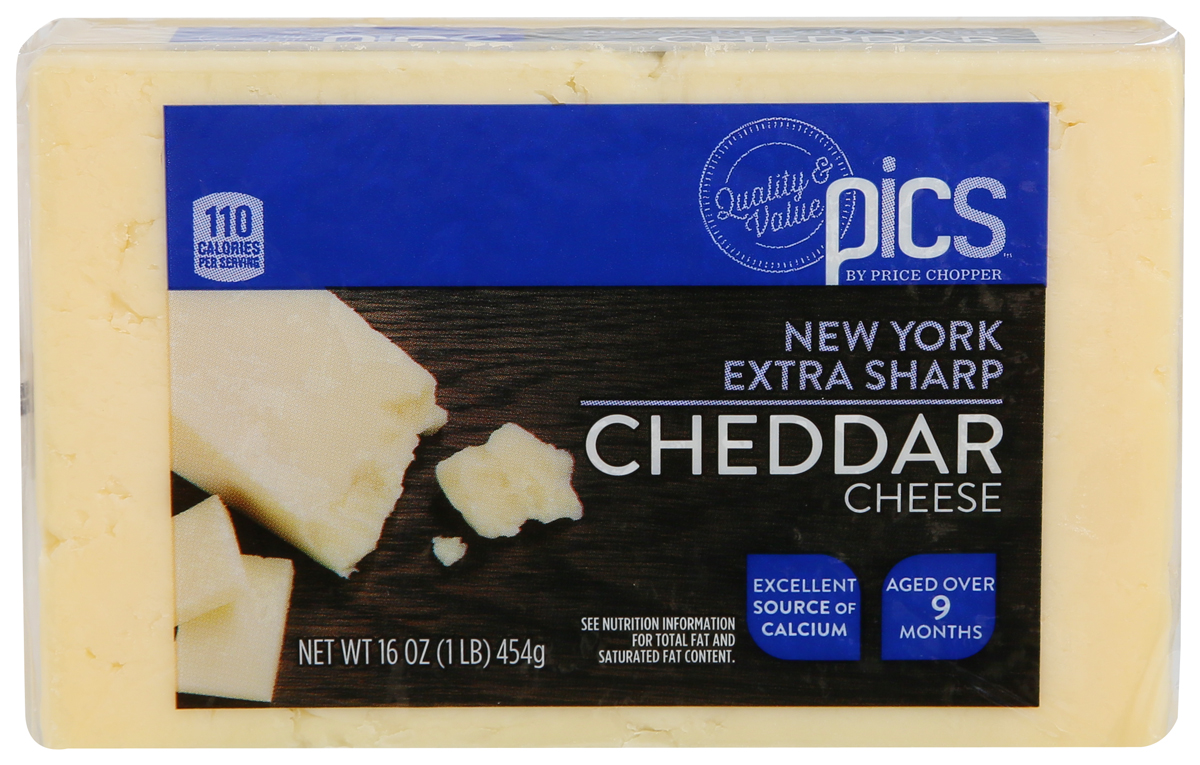

At Price Chopper and Market 32, we know one thing – making sure we have the best quality foods in our own brands brings value and enjoyment to our customers and communities. In business over 80 years, we also know that working with our local agricultural producers is a great way to deliver on that promise, and our PICS long process, naturally aged, award winning cheddar is a great example.

At Price Chopper and Market 32, we know one thing – making sure we have the best quality foods in our own brands brings value and enjoyment to our customers and communities. In business over 80 years, we also know that working with our local agricultural producers is a great way to deliver on that promise, and our PICS long process, naturally aged, award winning cheddar is a great example.

Did you know – the most popular cheese in America is cheddar? This spring, with friends from the American Dairy Association Northeast, I visited the cheese makers that create this wonderful cheese, and saw firsthand how hard they work to make it. We partner with Great Lakes Cheese Company, located in Adams, NY, in the heart of New York dairy country. They have been here over 40 years, and are committed to the New York North Country, so much so that they doubled production capacity in 2009. Experts that have crafted their process over time, they make several types here – mild, sharp, and extra sharp New York cheddar cheese to name a few. They also process the whey portion as part of sustainability efforts and for new product ingredient markets.

John Jennings, Plant Manager for over 40 years, and Nathan Pistner, Assistant Plant Manager, were proud to show us the inner workings of this modern facility, and most proud of their 122 employees. There is a lot of workmanship in this cheese – over 300 years of combined expertise on first shift alone!

Did you know – the most popular cheese in America is cheddar? This spring, with friends from the American Dairy Association Northeast, I visited the cheese makers that create this wonderful cheese, and saw firsthand how hard they work to make it. We partner with Great Lakes Cheese Company, located in Adams, NY, in the heart of New York dairy country. They have been here over 40 years, and are committed to the New York North Country, so much so that they doubled production capacity in 2009. Experts that have crafted their process over time, they make several types here – mild, sharp, and extra sharp New York cheddar cheese to name a few. They also process the whey portion as part of sustainability efforts and for new product ingredient markets.

John Jennings, Plant Manager for over 40 years, and Nathan Pistner, Assistant Plant Manager, were proud to show us the inner workings of this modern facility, and most proud of their 122 employees. There is a lot of workmanship in this cheese – over 300 years of combined expertise on first shift alone!

By the numbers, they receive 2,500,000 pounds of high quality milk from local dairy farms like Murcrest Farms per day, which becomes over 87 million pounds of cheese per year. (Cheese heaven?!) The farms they work with must meet high standards for cow care. Like the farms, this is a 24- hour, 365 days per year operation – cows don’t take any days off. They use natural ingredients, and move the cheese through the process using air, to protect the curd integrity and texture. These steps ensure a premium, reliable, delicious cheese on your table every time!

The tour showed us all of the work and time that goes into making this cheddar – there are quality tests built into every step, and they continue throughout the entire year of aging. Once they have the cheese in production, and process the whey, they turn the remaining liquid back into clean water that helps keep the plant clean – another sustainability process they are very committed to. Tradition and technology are part of making sure they are serving their own communities and partners well.

You will be sure to enjoy these wonderful cheddars, as a great snack, or as part of a new recipe – check out the links below for some delicious ideas!

https://www.pricechopper.com/recipes/7865/Jalapeno-Cheddar-Cheese-Corn-Muffins

https://www.pricechopper.com/recipes/14338/Mini-Apple-Pies-with-Cheddar

https://www.pricechopper.com/recipes/10988/Cheddar-Stuffed-Mini-Meatloaves-with-Chipotle-Glaze – this would be a great stuffed burger, too!

—

Ellie Wilson, MS, RDN Senior Nutritionist

Ellie Wilson, MS, RDN Senior Nutritionist

Dairy farming is New York State’s primary agricultural industry. It is a tight knit community, and encompasses more than the farm families – dairy milk haulers, the tireless truckers that move milk from farm to plant, are also an integral and symbiotic part of this landscape.

Husted Trucking, based a few miles from Terry’s farm, picks milk up from about 200 farms across a 50 mile radius. Thirty-two trucks and experienced drivers maintain this lifeline connection to plants and processors, with Chobani receiving a lion’s share of local milk. As part of our day, we met the company’s second generation owners, David and Penny. Their son, the third generation, is on the runway, working in the office while we learn more about their operation.

By the numbers, they receive 2,500,000 pounds of high quality milk from local dairy farms like Murcrest Farms per day, which becomes over 87 million pounds of cheese per year. (Cheese heaven?!) The farms they work with must meet high standards for cow care. Like the farms, this is a 24- hour, 365 days per year operation – cows don’t take any days off. They use natural ingredients, and move the cheese through the process using air, to protect the curd integrity and texture. These steps ensure a premium, reliable, delicious cheese on your table every time!

The tour showed us all of the work and time that goes into making this cheddar – there are quality tests built into every step, and they continue throughout the entire year of aging. Once they have the cheese in production, and process the whey, they turn the remaining liquid back into clean water that helps keep the plant clean – another sustainability process they are very committed to. Tradition and technology are part of making sure they are serving their own communities and partners well.

You will be sure to enjoy these wonderful cheddars, as a great snack, or as part of a new recipe – check out the links below for some delicious ideas!

https://www.pricechopper.com/recipes/7865/Jalapeno-Cheddar-Cheese-Corn-Muffins

https://www.pricechopper.com/recipes/14338/Mini-Apple-Pies-with-Cheddar

https://www.pricechopper.com/recipes/10988/Cheddar-Stuffed-Mini-Meatloaves-with-Chipotle-Glaze – this would be a great stuffed burger, too!

—

Ellie Wilson, MS, RDN Senior Nutritionist

Ellie Wilson, MS, RDN Senior Nutritionist

Dairy farming is New York State’s primary agricultural industry. It is a tight knit community, and encompasses more than the farm families – dairy milk haulers, the tireless truckers that move milk from farm to plant, are also an integral and symbiotic part of this landscape.

Husted Trucking, based a few miles from Terry’s farm, picks milk up from about 200 farms across a 50 mile radius. Thirty-two trucks and experienced drivers maintain this lifeline connection to plants and processors, with Chobani receiving a lion’s share of local milk. As part of our day, we met the company’s second generation owners, David and Penny. Their son, the third generation, is on the runway, working in the office while we learn more about their operation.

David started working with his father hauling milk cans in 1953. Like farming, milk transportation gets no days off – no weekends, no weather can interrupt the schedule. Dairy farms are located on narrow, uneven back roads – drivers must be dedicated and very skilled, navigating through rain, sleet or snow. Drivers are also part of the quality and safety team – every milk load is tested. Drivers take samples from the farm holding tank, and the milk is tested again before it enters the plant to be sure there is no quality issue. The management team works with brokers to direct and deliver fresh milk orders that change daily.

The trucks take milk to the plants, and the leftover whey back to the farms – a sustainable circle that promotes land and animal health. The truck are washed and sanitized after they deliver the milk to the plant. The whole system is regularly inspected– local, state and federal agencies all have a role. Regionally, farms collectively manage their food safety and must pass all inspections or they lose their market – their ability to sell their milk. All of these regulatory requirements ensure a safe supply chain from cow-to-cup.

Commitment and collaboration rise like cream to the top of this discussion – David’s dedication to his team, longstanding working relationship and friendship with Terry, and

David started working with his father hauling milk cans in 1953. Like farming, milk transportation gets no days off – no weekends, no weather can interrupt the schedule. Dairy farms are located on narrow, uneven back roads – drivers must be dedicated and very skilled, navigating through rain, sleet or snow. Drivers are also part of the quality and safety team – every milk load is tested. Drivers take samples from the farm holding tank, and the milk is tested again before it enters the plant to be sure there is no quality issue. The management team works with brokers to direct and deliver fresh milk orders that change daily.

The trucks take milk to the plants, and the leftover whey back to the farms – a sustainable circle that promotes land and animal health. The truck are washed and sanitized after they deliver the milk to the plant. The whole system is regularly inspected– local, state and federal agencies all have a role. Regionally, farms collectively manage their food safety and must pass all inspections or they lose their market – their ability to sell their milk. All of these regulatory requirements ensure a safe supply chain from cow-to-cup.

Commitment and collaboration rise like cream to the top of this discussion – David’s dedication to his team, longstanding working relationship and friendship with Terry, and pride in their company’s heritage and role are evident. The boxes are always checked, the additional work done, the extra mile driven to protect their cargo and deliver it safely and efficiently to its destination.

Three cups of milk make one cup of Greek yogurt. To highlight this part of our tour, we have some wonderful recipes to sip (or slurp!) and transform Greek yogurt into a delicious smoothie. Check them out, and tell us which one is your favorite!

Pack a delicious, protein punch – substitute Greek yogurt in recipes and power up taste and nutrition. Check the blog next week for the rest of our Greek yogurt tour with Chobani!

https://www.pricechopper.com/recipes/9177/Cranberry-Berry-Smoothie

http://www.chobani.com/culture/recipes/berry-banana-smoothie/

http://www.chobani.com/culture/recipes/mango-liquados/

http://www.chobani.com/culture/recipes/pina-colada-simply-100-smoothie/

http://www.eatingwell.com/recipes/pineapple_green_smoothie.html

http://www.eatingwell.com/recipes/strawberry_banana_protein_smoothie.html

pride in their company’s heritage and role are evident. The boxes are always checked, the additional work done, the extra mile driven to protect their cargo and deliver it safely and efficiently to its destination.

Three cups of milk make one cup of Greek yogurt. To highlight this part of our tour, we have some wonderful recipes to sip (or slurp!) and transform Greek yogurt into a delicious smoothie. Check them out, and tell us which one is your favorite!

Pack a delicious, protein punch – substitute Greek yogurt in recipes and power up taste and nutrition. Check the blog next week for the rest of our Greek yogurt tour with Chobani!

https://www.pricechopper.com/recipes/9177/Cranberry-Berry-Smoothie

http://www.chobani.com/culture/recipes/berry-banana-smoothie/

http://www.chobani.com/culture/recipes/mango-liquados/

http://www.chobani.com/culture/recipes/pina-colada-simply-100-smoothie/

http://www.eatingwell.com/recipes/pineapple_green_smoothie.html

http://www.eatingwell.com/recipes/strawberry_banana_protein_smoothie.html

©Mitch Wojnarowicz Photographer Ives farm Bainbridge NY and Chobani plant tour, New Berlin NY for American Dairy Association (ADA) Client is solely responsible for securing any necessary releases, clearances or permissions prior to using this image. 20160517 Not a royalty free image. COPYRIGHT PROTECTED www.mitchw.com 518 843 [email protected] ANY USE REQUIRES A WRITTEN LICENSE