Ellie Wilson

MS, RDN, CDN

February is Lactose Awareness Month. Lactose is a type of carbohydrate or natural sugar found in dairy products. Some adults and children are sensitive to lactose, meaning, some dairy products may cause stomach upset. Dairy products are an important source of 13 essential nutrients; understanding how to manage this challenge is important to ensure you and your family don’t lose access to favorite foods and their nutrient-rich health benefits, such as calcium and phosphorus, that strengthen teeth and bones, whey and casein proteins that promote lean muscle mass, and Vitamins A, B2, B12, and Vitamin D, all important for energy, immune system health and production of red blood cells.

Lactose sensitivity (also known as intolerance) occurs for different reasons, ranging from genetics, age, medical conditions and cancer treatments. It can occur at any time of life, and may be very mild to more acute, depending on the cause. How much milk and dairy we regularly enjoy also plays a role – for example, if you regularly had milk and other dairy foods as a child, but gradually reduced the quantity over time, you may be surprised by a new sensitivity. For some people, lack of dairy intake over time changes how much we can make of the lactase enzyme, key to being able to digest dairy foods.

The good news is, there are still a lot of options. The more you know, the more confident and comfortable you will be.

Enjoy:

- Lactose-free milk and ice cream – all the great taste and benefits of regular milk without the lactose. Bonus – these can also substitute for milk in any recipe!

- Trace amounts – 1 gram or less per serving: Natural cheeses, cream, whipped cream, butter, American cheese, cream cheese, and ricotta cheese.

- Small amounts – 3 – 5 grams of lactose per serving: Cottage cheese, traditional and Greek yogurts. The cultures in yogurts break down some lactose naturally – try different styles and brands. Small servings may keep them on your plate without symptoms.

- Experiment with fermented options like Kefir – again, the cultures that help create the flavor break down some lactose during fermentation.

Good to Know:

Whether the sensitivity developed over time or is a reaction to a recent health change, many people can restore their gut function by having small amounts of milk/dairy foods over time.

- Lactose sensitivity may be temporary, especially if it occurs suddenly after a bout with a stomach bug or after cancer treatment involving the Gi tract. The lactase enzyme is produced in cells that may get temporarily knocked out but are restored as the body recovers from illness or treatment.

- Enjoy milk/dairy with meals or snacks – together, they slow digestion down and allow enough time for the enzyme to break lactose down, reducing or eliminating symptoms. Cookies and milk, fruit and yogurt, and cheese on a sandwich are all ideas to explore.

- Lactose sensitivity is not a dairy allergy – your MD can help you sort out which one it is.

- Whether the sensitivity developed over time or is a reaction to a recent health change, many people can restore their gut function by having small amounts of milk/dairy foods over time.

Good Moooove – Take these tips to store and explore!

Learn more about the American Dairy Association here!

Check out these lactose-free recipes!

Chocolate-Raspberry Smoothie Bowl

Creamy Papaya Protein Shake

Cherry Milk Steamer

Mint Chocolate Chip Milk

Chocolate Peanut Butter Milk

Ellie Wilson

MS, RDN, CDN, FAND

October 12th is National Farmer’s Day! We are grateful for all farmers – big and small, especially our local dairy farmers that ensure we have great quality fresh milk in our stores! Milk is a delicious choice; an affordable, convenient and sustainable drink that has been an important part of foodways around the world for thousands of years. We have some great products in our milk case and dairy aisle – see the insights below as we spotlight a few choices for you!

Good to know – Dairy farmers work 365 days per year, taking great care of their cows and ensuring the highest quality and safety standards from cow to cup. Dairy farmers are also continually driving the science and practices that make dairy farming sustainable in every way possible. Learn more about the many ways dairy farms are ensuring sustainability is top of mind! Dairy Farming Environmental Impact | American Dairy Association NE.

Chocolate Milk is a wellbeing champion! It is the most popular drink in schools, which is good news – it is the leading source of critical nutrients for millions of school children. Milk and chocolate milk fuel growth and hydration, offering a thirteen-nutrient package that includes protein for muscle growth, calcium and magnesium that build lifelong bone health, and Vitamin D and potassium, two nutrients that are often below intake recommendations for children and adults. Research shows that children who drink chocolate milk have higher overall nutrient intakes than those who do not, while keeping adding sugars to a minimum.

Lactose-free Milk – Some people have challenges digesting lactose, the natural sugar in milk. This is called Lactose Intolerance. It is not an allergic reaction – it is very manageable using real milk products that have reduced that lactose content, along with strategies that can even help restore lactose digestion over time. Lactose-free milk can be a game changer, ensuring those with this issue can still enjoy milk and get all its nutrition benefits. Dairy products that are naturally low in lactose, such as natural cheese and yogurts, can usually be enjoyed by those navigating this concern.

Explore our milk and dairy aisles, there is always something delicious and nutritious waiting there for you! Scan the QR code for this amazing Pumpkin Pie In a Glass Smoothie recipe and join us as we celebrate #NationalFarmersDay!

#UndeniablyDairy

Check out this delicious Pumpkin Pie in a Glass!

Written by our friends at the American Dairy Association

Milk goes from farm to grocery store in about 48 hours 365 days a year. Have you ever wondered how it is possible for this process to happen so quickly? Let’s talk about milk’s journey from cow to cup.

On the Farm

Dairy farmers like Kings Brother Dairy make sure milk is safe and nutritious every day and that process starts at the farm.

In the Barn

Cows need to be cared for to stay content and healthy – and produce great milk. Dairy farmers work 365 days a year making sure cows are comfortable, with the right food, water, bedding and veterinary care. Whether a farm is big or small, the cows and land are well cared for.

Transportation

Tanker trucks pick milk up at the dairy farm – for some farms, this is multiple times each day. The milk is tested for safety and quality on the farm and again at the dairy processing plant to ensure every tanker truck of milk is safe and pure.

Milk Processing

Garelick is the processor that Price Chopper uses to provide strict quality controls at every step of processing to ensure freshness, purity and great taste. Human hands never touch the milk and strict temperature rules must be followed.

Once at the processing plant, milk is pasteurized, homogenized, and bottled or turned into cheese, yogurt or another delicious dairy product.

At Price Chopper and Market 32, we strive to keep milk fresh, cold and well stocked so you can bring it home to your family.

Whether you choose skim, whole milk or lactose-free milk, your milk comes from a good place, and you can feel good about the 13 essential nutrients it provides – as well as the care the farmer puts into the cows and planet.

Written by our friends at the American Dairy Association

Focus on including dairy in your kids’ meals during this back-to-school time. Milk, cheese and yogurt help kids grow up strong because they deliver a unique combination of essential nutrients. They also keep kids energized throughout their day, keeping them focused throughout the school day.

Here are two easy ways to fuel their day with dairy:

- Have a smoothie before school.

A smoothie made with real milk and yogurt is a simple and easy way to pack a lot of nutrition into one glass and kids love them! This delicious strawberry acai smoothie is the perfect way to start their day.

Strawberry Acai Smoothie Recipe

Ingredients:

½ cup milk

6 ounces strawberry yogurt

1 cup slide strawberries, fresh or frozen

1-ince piece of ginger, peeled

2 small beets, cooked and cooled

1 teaspoon acai powder

Preparation:

In a blender, combine milk, yogurt, strawberries, ginger and beets. Blend over high speed until smooth. Serve immediately.

2. Include dairy in lunchboxes.

Adding individual milks, snacking cheeses and yogurts to your kid’s lunch boxes is another easy way to fuel their day with dairy. Not only are these dairy products affordable, accessible, and nutritious they have key nutrients that play an important role in child nutrition by supporting growth and development.

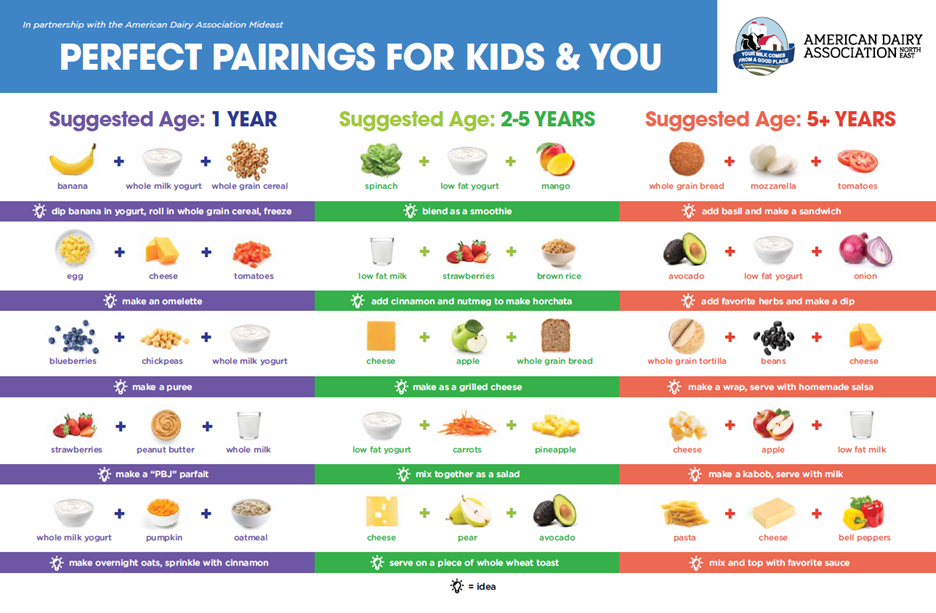

Try a few of these pairings from this resource:

Ellie Wilson

MS, RDN, CDN, FAND

Food and health are deeply connected – the quality and quantity of nutrient rich foods throughout our life is directly related to how we grow and stay well. I count our regional access to diverse types of farms and agricultural products as a big win for our customers and communities, especially the number of dairy farms and the range of products dairy contributes to wellbeing. The Dietary Guidelines for Americans₁ persistently recommend 3 servings of dairy per day because it is a familiar, accessible and delicious way to get a significant amount of nutrients in each serving – some of which are nutrients, like calcium, potassium, Vitamin D, and fiber, we are not getting enough of for optimal health.₂ Check out how dairy foods fuel wellness for all ages and stages!

Infants and toddlers – benefit from Mom’s intake of dairy, such as milk and yogurt, while they are pregnant and nursing, with B12 and Choline supporting red blood cell production for Mom and baby, and the growth of infant brains. Toddlers transition to whole milk at about 1 year old because it has a powerful matrix of nutrients that support overall physical and cognitive health and growth. In fact, milk and water are the primary beverages recommended for toddlers and children through age 5. For them, dairy fuels growth, muscle and bone development,₃ and helps build immunity, with its protein, Vitamin A and D, zinc and selenium content.₄ This is also why milk and dairy are such a focus in schools – both regular and chocolate milk fuel growth and wellness throughout their school years. During that time milk and dairy are considered “vehicle” foods – they deliver a range of critical nutrients whether they are enjoyed alone or with other foods, like fruit and whole grains, when snacking or eating a meal. Teens are often way below the dairy intake they need, so encouraging some deliberate focus on dairy intake is a smart move. Adolescence is a unique time of growth, particularly for increasing bone mass and density to prepare for adulthood needs.₁ We are only ‘young’ for the first 18 years – the quality and quantity of the remaining 60+ years is partially built on the food and health habits of those critical growing stages.

The Summer 2024 Olympics are in full swing, which brings me to fueling adults and performance, whatever that may be, including sports, hobbies, training and working the full spectrum of jobs and careers, having families and managing the general chaos of busy lives. All of that requires fuel to support your best efforts, whether it be to win the gold medal, or “win” from having the health, stamina, and energy to seek your most optimal path through life. We all have a need to ensure we can perform whatever actions required to live well and reach our goals. For those Olympians, who may be participating in more than one event, chocolate milk, yogurt and cheese sticks are go-to refuelers, providing hydration, electrolytes, protein and carbohydrates to refuel and recover quickly between sports events. Hard-working adults have a similar level of stress on body systems – maintaining a regular habit of enjoying dairy may be just the thing you need to enjoy the fruits of your labor and everything else!₁

Dairy delivers wholesome goodness, again and again, to our glasses and plates, supporting the wellbeing, energy, enjoyment and vitality that brings richness to our lives. Enjoy!

Sources:

₁U.S. Department of Agriculture and U.S. Department of Health and Human Services. Dietary Guidelines

for Americans, 2020-2025. 9th Edition. December 2020. Accessed at https://www.dietaryguidelines.

gov/sites/default/files/2020-12/Dietary_Guidelines_for_Americans_2020-2025.pdf

HEI Scores for Americans | Food and Nutrition Service (usda.gov)

Weaver CM, Gordon CM, Janz KF, et al. The National Osteoporosis Foundation’s position statement

on peak bone mass development and lifestyle factors: a systematic review and implementation

recommendations. Osteoporos Int. 2016;27(4):1281-1386. doi:10.1007/s00198-015-3440-3.

Calder PC, Carr AC, Gombart AF, Eggersdorfer M. Optimal nutritional status for a well-functioning immune system is an important factor to protect against viral infections. Nutrients. 2020;12(4):1181.

Written by our friends at the American Dairy Association

June is National Dairy Month and there is no better way to celebrate than with Real Smoothies made with Real Dairy. A smoothie made with wholesome milk or yogurt is a delicious way to get high-quality protein and other essential nutrients that your body needs to help fuel your day. Making smoothies with real dairy is a great way to honor the hardworking dairy farmers behind the milk and dairy products making it to your table every day.

A refreshing smoothie is a simple and easy way to pack a lot of nutrients into one glass. To get the most nutrition from your smoothie, make it with real milk or yogurt.

Milk makes an excellent base for any smoothie. Milk is a go-to source of protein as well as a powerful package of 13 essential nutrients, including calcium, phosphorus, and several B vitamins. Milk also has immunity-boosting nutrients like Vitamin A, Vitamin D, Zinc, and protein. Add more or less milk, depending on how thick you like your smoothie.

Yogurt also makes a great addition to a smoothie. Yogurt is another excellent source of protein and 9 essential nutrients. All yogurts are made with live and active cultures, and some also provide probiotics – or good bacteria – that may help maintain digestive health, boost immunity, fight infection and protect against diseases. Greek yogurt is thicker and creamier in texture because it is strained during processing to remove liquid whey, which is also why Greek yogurt is higher in protein and lower in lactose and calcium.

Check out these delicious smoothie recipes that can be made with real milk and Greek yogurt!

Peanut Butter Smoothie

Ingredients:

- 1 cup milk

- 1 cup vanilla yogurt

- 1 banana, frozen

- 2 tablespoons smooth peanut butter

- Garnish: mini chocolate chips

Preparation:

- In a blender, combine milk, yogurt, banana, and peanut butter. Pour into glasses and top with chocolate chips. Serve immediately.

Spinach Orange Smoothie

Ingredients:

- 2 mandarins, peeled

- 1 medium banana, peeled

- ½ cup raw spinach

- 2 cups milk

- 1 cup vanilla yogurt

Preparation:

- In a blender, combine Mandarin oranges, banana, Spinach, milk, and vanilla yogurt. Blend on high until smooth and creamy. Serve immediately.

Click here find these amazing recipes and more!

Written by our friends at the American Dairy Association

National Dairy Month is celebrated annually during June to recognize the contributions of the dairy industry and the hardworking dairy farmers behind the milk and dairy products making it to your grocery store shelves every day. This year, we want to focus on real milk and yogurt tubs to make a delicious, filling smoothie. What better time for an ice cold drink than summertime?

A smoothie made with real, wholesome milk or yogurt is a delicious way to get high-quality protein and other essential nutrients that your body needs to help fuel your day.

Use Real Dairy as the base of the smoothie.

- Milk makes an excellent base for any smoothie. Milk has a significant amount of protein as well as a powerful package of 13 essential nutrients including calcium, protein, phosphorus, vitamin D, vitamin A, and several B vitamins. Add more or less milk depending on how thick you like your smoothie.

- Yogurt also makes a great base for a smoothie. Yogurt is another excellent source of protein and 9 essential nutrients. Most yogurts are made with live and active cultures, and some also provide probiotics – or good bacteria – that may help maintain digestive health, boost immunity, fight infection and protect against diseases.

Are you a dairy lover interested in learning more about the history of Dairy Month? Check out more here!

Where does your milk come from?

Click here to meet dairy farming families in the Northeast.

Click here to meet dairy farming families in New England.

Learn more about dairy farming in the Northeast at AmericanDairy.com and in New England at NewEnglandDairy.com

Ellie Wilson

MS, RDN, CDN

June is National Dairy Month, and we have a lot of delicious and nutritious ways to celebrate with you all month long! As a registered dietitian-nutritionist, and a dairy lover, I am very sure dairy is the real deal – wholesome, versatile and a culinary champion used in an amazing variety of foods and recipes. To kick off this celebration, we have some great smoothie recipes to share! They are the perfect way to pack the benefits of Real Dairy into an easy-to-enjoy treat!

Fueling up with the full package of 13 nutrients milk adds to your glass is a great way to honor the hard work of the farmers that ensure it is available to you and your family every day. Those nutrients include calcium, phosphorous and B vitamins, which support bone strength and energy metabolism. Milk is a good source of high-quality protein, and contains Vitamin A, Vitamin D, and zinc. Together they help build immunity, support healing, and help grow and protect muscles. Traditional and Greek yogurt are made with live cultures and contain some probiotics, which improve gut health. So many benefits!

Greek yogurt is thick and creamy, its satisfying texture delivered by straining some of the liquid whey, resulting in higher protein content and lower lactose and calcium. You can use milk and Greek yogurt in your Real Dairy Smoothie, and change the recipe amounts to taste if you like!

We celebrate throughout National Dairy Month – add these ideas to your calendar and join in the fun all month long!

June 1 – World Milk Day – Lift your Glass!

June 4th – Cheese Day

June 7th – Choc Ice Cream Day

June 14th – Strawberry Shortcake Day

June 20th – Milkshake Day

June 20th – Ice Cream Soda Day

June 21 – Smoothie Day

June 25th – Strawberry Parfait Day – (could be a yogurt and strawberry parfait)

June 27th Ice Cream Cake Day

Mia Teal

Marketing Coordinator, Paid Media

It’s June – do you know what that means? It is National Dairy Month! We are celebrating all the creamy goodness of dairy this month, ranging from milk, cheese, ice cream, and everything in between! At Price Chopper and Market 32, we have a surplus of dairy products to offer, including our new PICS pint ice cream! Be sure to check them out at the end of this article.

National Dairy Month was originally just “National Milk Month” as a way to encourage people to drink more milk. However, this eventually became “National Dairy Month” by the National Dairy Council as a way to promote the benefits that dairy products provide to us. We have so many recipes on our website for all our dairy lovers! Let’s take a look at a few…

Double Chocolate Chunk Cookie Ice Cream Sandwiches: Nothing beats an ice cream sandwich on a warm summer day! Be sure to check out our PICS ice cream for a wide variety of flavors.

Baked Buffalo Cheese Sticks: The best appetizer right at your fingertips!

Caramel Milkshake: This four-ingredient shake is sure to be a fan favorite!

Pepperoni & Mushroom Pizza: In a hurry? No need to worry! This pizza is easy to make and perfect for celebrating National Dairy Month!

Lucky Charms Frozen Yogurt Pie: Looking for something fun to make for your July 4th celebration? This frozen yogurt pie is flavorful and festive. Beware: This will go fast!

Philly Cheesesteak Dip: Take your homemade dip to the next level with this Philly Cheesesteak Dip!

Raise a Glass to Dairy Month!

Ellie Wilson, MS, RDN Senior Nutritionist